- Products

- Catalogs

- News & Trends

- Exhibitions

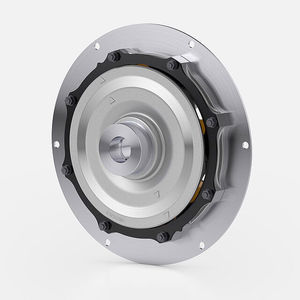

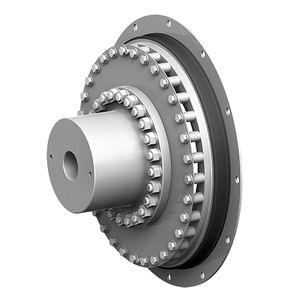

Rigid mechanical coupling HYDROFLEX MA-Rflangefor shipsfor shafts

Add to favorites

Compare this product

Characteristics

- Type

- rigid, flange

- Application domain

- for ships

- Applications

- for shafts

- Other characteristics

- torque, compact

Description

Machines like small excavators, forklifts, mini dumpers, asphalt machines, concrete pumps, agricultural machinery etc use hydrostatic drives from a combustion engine, directly connected with a hydrostatic pump via a coupling. The coupling conveys the required force from the engine to the pump and consequently ensures proper machine operation. The coupling must also be able to be installed and plugged into the smallest area under the pump installation flange of the engine, so that the hydraulic pump can be flange-mounted directly to the engine. Hydrostatic applications generally require a rigid coupling to operate hydraulic pumps and similar machines with low torque of inertia below the critical speeds, whereby possible damaging resonances from the machine’s operating speed range are removed. VULKAN has developed its HYDROFLEX coupling program for this application – also known as HYDROFLEX MA-R, a rigid coupling with a special nylon core, suitable for direct connection between diesel engines and hydraulic pumps.

HYDROFLEX MA-R versions

The HYDROFLEX MA-R is available in different sizes and SAE or NON-SAE configurations. It can also be fitted with flat, round or customer specific rotating assemblies to go with the most common diesel engine and pump type configurations.

Benefits

High torsion rigidity to ensure the operating speed as no damaging resonances

Nylon coupling core with high mechanical resistance, temperature resistance and stability

Compact design for limited space in the pump support

Clamping hub system to prevent wear or breaks on the pump shaft

Simple plug in assembly

Low maintenance

Simple and cost-effective adjustment option

Catalogs

No catalogs are available for this product.

See all of VULKAN Marine‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.