- Products

- Catalogs

- News & Trends

- Exhibitions

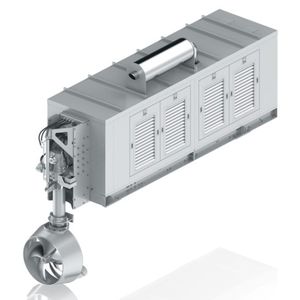

Ship monitoring system thruster

Add to favorites

Compare this product

Characteristics

- Application domain

- for ships

- Applications

- thruster

Description

Optimized ship operation thanks to predictive maintenance

The ZF Condition Monitoring System ProVID for marine propulsion systems increases operational reliability by monitoring the performance and the overall condition of the core components in thrusters. The intelligent CMS ProVID from ZF shows how efficiency, reliability and safety on board can be further increased thanks to integrated sensors and advanced data analysis tools.

Advantages

Early detection of changes in the performance of components

Less downtime, lower operating costs

Increased availability and extended lifetime of monitored systems and components

Maximize vessel's operation time

Regular reports with condition-based recommendations for maintenance

Security on board and in port

Remote support from ZF experts worldwide

Function

Thanks to the use of sensors and diagnostic tools, information about components of the propulsion system can be collected.

ZF Condition Monitoring System ProVID provides data on the status of:

Gears in upper and lower gearboxes

Propeller balance

Balance of internal shafts

Temperature

Saturation level of oil

Contamination by conductive material

The monitoring of oil regarding to conductive particles and water content can optionally be integrated into the CMS ProVID.

With the help of the ProVID processor, data is collected, saved, and transmitted to the ZF data analysis center through a cloud-based solution.

The collected data is analyzed, evaluated and transformed into a dashboard using algorithms specially developed by ZF. Operators can then identify at an early stage which components may need to be serviced or replaced.

Catalogs

No catalogs are available for this product.

See all of ZF Italy‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.