- Maritime equipment

- Water, Waste, Emissions and discharge reduction

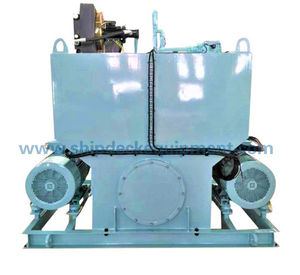

- Ship hydraulic power unit

- Zhongyuan Ship Machinery Manufacture (Group) Co.,

Ship hydraulic power unit Bottomfor doors

Add to favorites

Compare this product

Characteristics

- Application domain

- for ships

- Applications

- for doors

Description

The split barge bottom door hydraulic power unit is used to drive open-body cylinder and other special-purpose hydraulic cylinders. This hydraulic system is composed of hydraulic pump, control valve group, differential valve group, hydraulic oil cylinder pressure maintaining valve group, hydraulic oil cylinder overload valve group, hydraulic oil cylinder, etc. In order to ensure that the technical performance and functions of the oil cylinder can achieve the best results, the system is controlled by an open constant power pump, and the key components are imported valves. The system mainly consists of two (one working, one standby) 11kW motor driven hydraulic pump to provide pressure oil, and the corresponding hydraulic control valve drives the cylinder to open and close the body. In addition, the cylinders are equipped with valve blocks for pressure holding, overload, differential and anti-cavitation.

Main Technical Specifications:

Class Certificate: CCS, NK, BV, ABS, DNV-GL, LR, KR, IRS, RS, RINA, Etc.

1. The working pressure of the hydraulic system is about 32MPa, and the maximum pressure is set to 42MPa.

2. The fuel tank has a capacity of 1500 liters.

The total installed power of the system is approximately 22 kW.

3. The main pressure parameters of each cylinder

4. Calculation

2. Hydraulic system supply content (one set of ship)

1) Hydraulic power station, including:

1.1 One main fuel tank assembly, 1500L, including:

a) Liquid level gauges, oil temperature gauges, air filters, heaters, etc.;

b) The return oil filter has clogging display and alarm;

c) High temperature alarm, liquid level alarm;

Catalogs

No catalogs are available for this product.

See all of Zhongyuan Ship Machinery Manufacture (Group) Co.,‘s catalogsOther Zhongyuan Ship Machinery Manufacture (Group) Co., products

Hydraulic Power Unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.