Juno Composites Ltd

About Us

What We Do

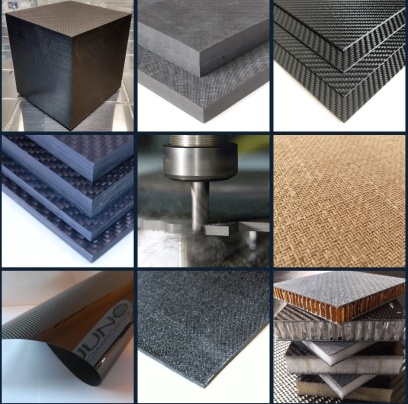

Juno Composites design, manufacture and machine advanced composite material solutions in our state-of-the-art ISO 9001 accredited facility.

We make your products LIGHTER through clever design and thanks to our proprietary manufacturing technology, we deliver FASTER, at lower cost and higher quality.

Our holistic approach offers you a GREENER material solution that will lower your carbon footprint.

Our Process

Juno Composites collaborates closely with our customers in a variety of industries, providing a diverse portfolio of standard and tailored semi-finished and final machined advanced composite material solutions. Our value-added services and capabilities include: the Design of composite materials, the Manufacture of the optimised material, and the Machining of final component parts

Our values

Design

We have extensive experience in Advanced Composite Material Design, to help you exploit the many advantages of advanced composites in your application, whether your project is for drones and UAV’s, marine applications, automotive, medical equipment, robotics and automation, or musical instruments.

We will assist you in bridging the skills gap in material design and selection, as well as optimising material performance and cost for your project.

Manufacture

We can assist you in the Manufacture of your product, whether you’re at the prototyping stage or have volume production requirements in our state-of-the-art ISO 9001 certified manufacturing facility. Examples of the many product forms we manufacture include:

Carbon fibre veneers, sheets, plates, billets, and sandwich panels with different skin types, for example, carbon and glass fibre, that can be set on different types of cores, including Rohacell, PVC, recycled PET, and honeycomb cores.

We have many ‘off-the-shelf’ product forms available for you to get started building your product right away.

CNC Machining

Juno Composites also provides CNC machining and panel profiling on our off-the-shelf products and custom-designed materials, for example, sandwich panels with integrated hard points and monolithic plates with fibre orientation optimised to the loading envelope of your project and supplied to you ready for final assembly.

Complementary services we can provide you with include composite finite element analysis, coupon testing to determine material performance, contract manufacturing, and quality measurements via CMM.